Thanks to its height-adjustable tracked chassis, the SM 620.2 K is always right on track, even on uneven and rough terrain – and is also able to handle demanding screening tasks very quickly and reliably.

SPECIALS

The SM 620.2 K is mounted on a rugged tracked chassis with 500 mm wide tracks and at two travel speeds. An important upgrade over its predecessor – the SM 620 K Profi – is its Load Sensing System: This allows the machine to move and work at the same time, making the SM 620 K Plus capable of multitasking.

Another enhancement over the previous model is the Deutz engine: The applicable emissions regulations made it necessary to upgrade from Stage IIIB/Tier 3 to Stage IV/Tier 4 final. The tank capacity was also increased from the previous 300 liters to 400 liters now.

With its generous feed hopper capacity of 7.0 m³, the SM 620.2 K is on the same level as its siblings SM 620 SA and SM 720 SA Plus.

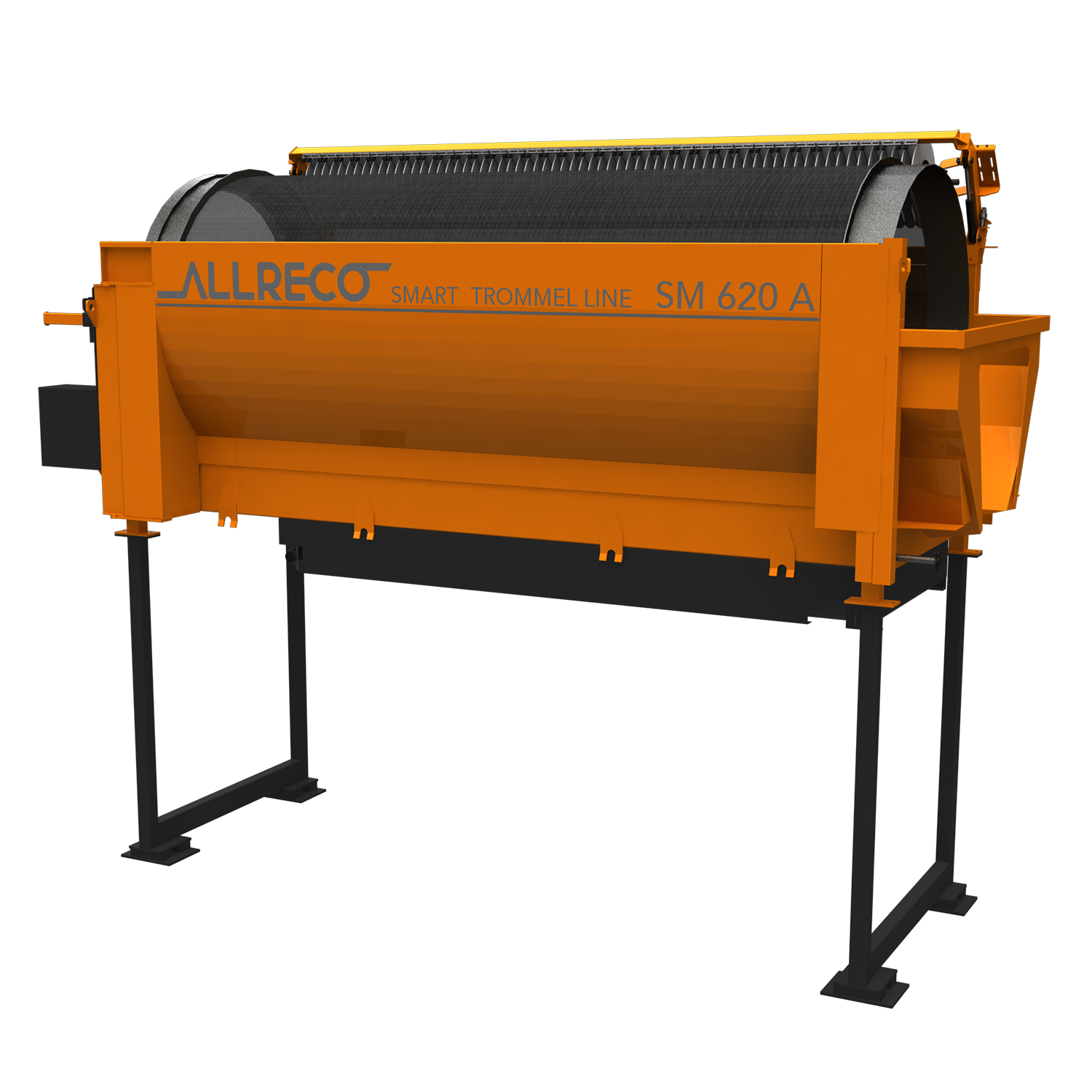

The SM 620.2 K drum screening machine is optimally equipped for screening almost all types of waste and raw materials – and thus making a forward-looking contribution to recycling.

APPLICAZIONI

- Waste wood processing

- Landfill mining

- Composting

- Commercial waste recycling

- Construction waste

BENEFICI

- Heavy-duty tracklaying chassis

- Self-propelled via remote control unit

- Large feed hopper with a capacity of more than 7 m³

- Hopper width even suited for very large loader buckets, loading height only 2.9 m

- Load sensing system allows, among other things, for moving and operating at the same time

- Track chassis with lifting kinematics for optimum levelling of machine on uneven terrain

- Fast changing system for trommel or star screen insert

- Diesel engine with low fuel consumption – exhaust standard stage V, low operation costs

- Highest throughput capacity

- Extensive standard safety equipment (e.g. intrusion protection, emergency stop, machine monitoring)

- Complete machine control placed in the rear

- Additional hydraulic connections for using numerous optional equipment