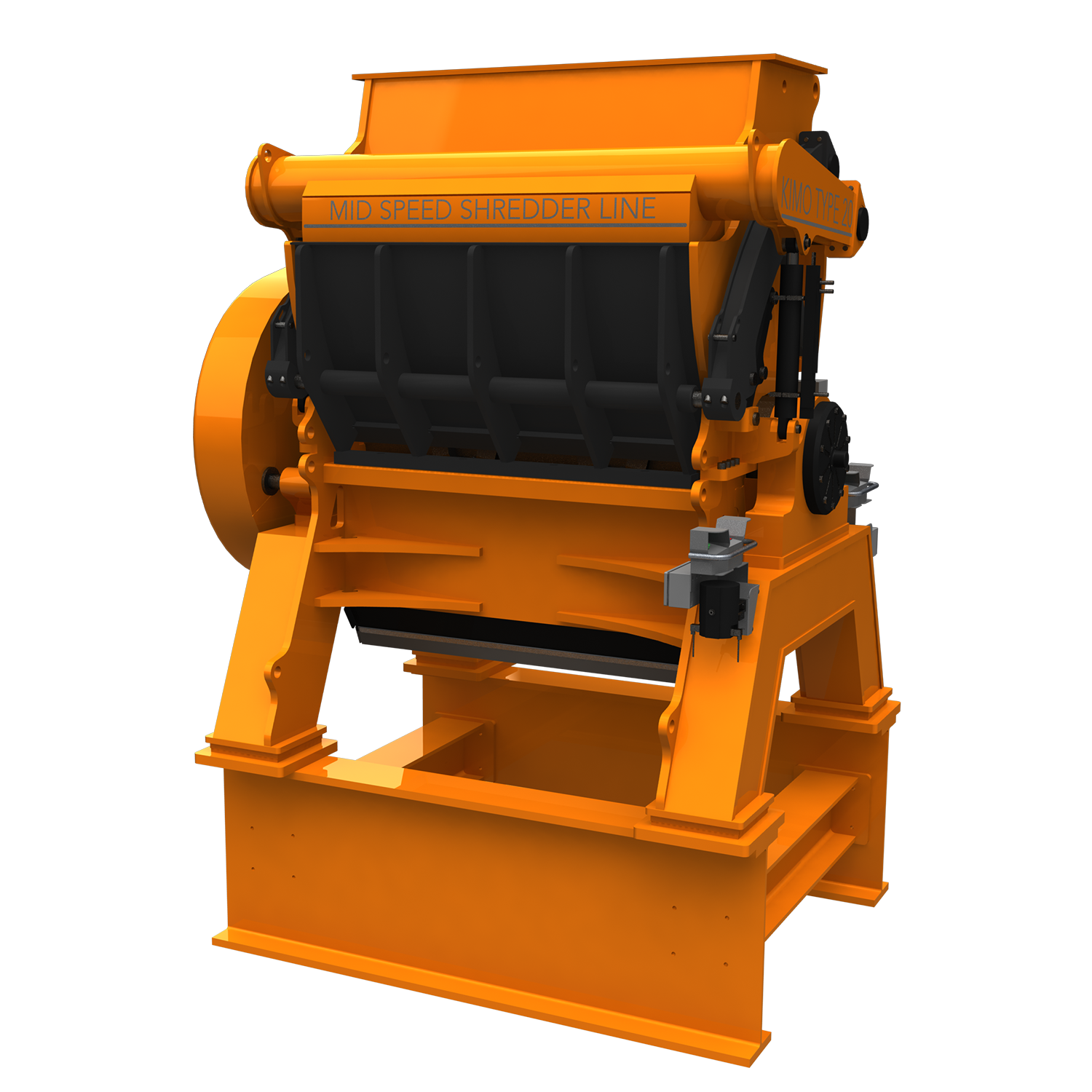

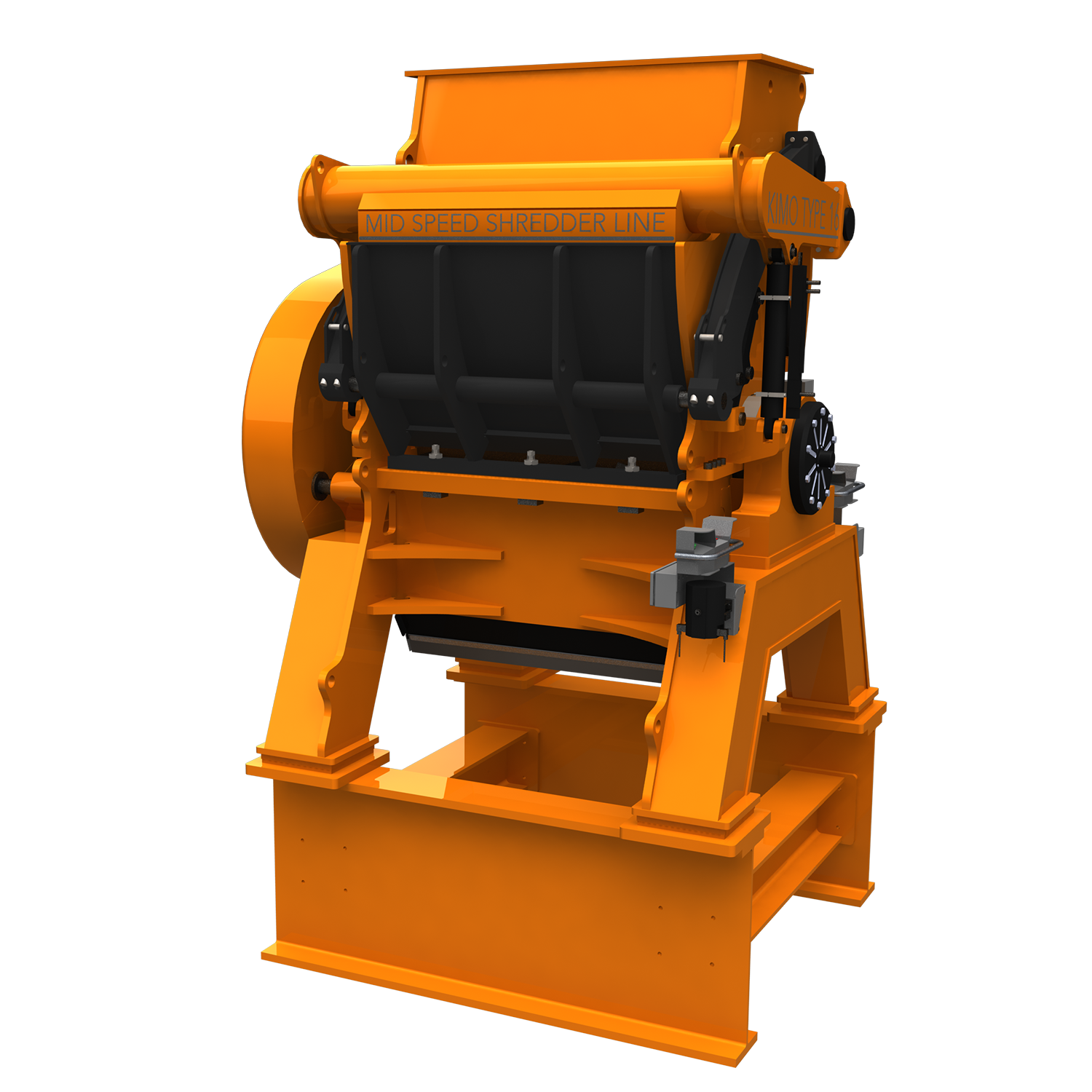

A true demonstration of grandeur in fine shredding: The KIMO Type 20 with its 2,000 mm long rotor and its 315 kW drive is highly recommended for operations with higher throughput rates. It reliably shreds everything, including cable and electronic waste.

SPECIALS

The KIMO Type 20 is Doppstadt’s largest fine shredder. It reliably shreds not only high and medium calorific waste but also more challenging materials like aluminium/copper scrap or waste electronic with occasional electric motors of up to 1.5 kg.

With a rotor diameter of 785 mm the KIMO Type 20 has at 2 m rotor length a similar screening area to a conventional cutting mill with a rotor length of 3 m, and thus delivers a similar throughput. In comparison to these conventional 3 m machines, the KIMO is stiffer due to its smaller width and only requires one drive instead of two. That makes the KIMO Type 20 so rugged that even large contaminants do not slow it down. Peak loads are effectively smoothened out as a result of the enormous flywheel mass of the heavy rotor and the large drive pulley such that the motor is continuously running at maximum load, and thus requires little buffer in terms of power. In relation to the achieved throughput the 315 kW motor is comparatively small and economical. Vibration during operation is reduced to a minimum thanks to the heavy frame and the support leg segments which are filled with polymer concrete to make them even heavier.

APPLICATIONS

- Refuse derived fuel processing

BENEFITS

- Long service life as a result of its heavy duty, rugged design

- Low energy consumption due to relatively small motor

- High throughput due to high tool holder leading to larger shredding chamber volume and aggressive intake behaviour

- High power reserve thanks to large drive pulley and rotor, thus high momentum of inertia

- Low vibration

- Easy to maintain due to large access panels and easy-to-change tools

- Adaptable friction clutch protects the machine against any damage caused by foreign solid objects