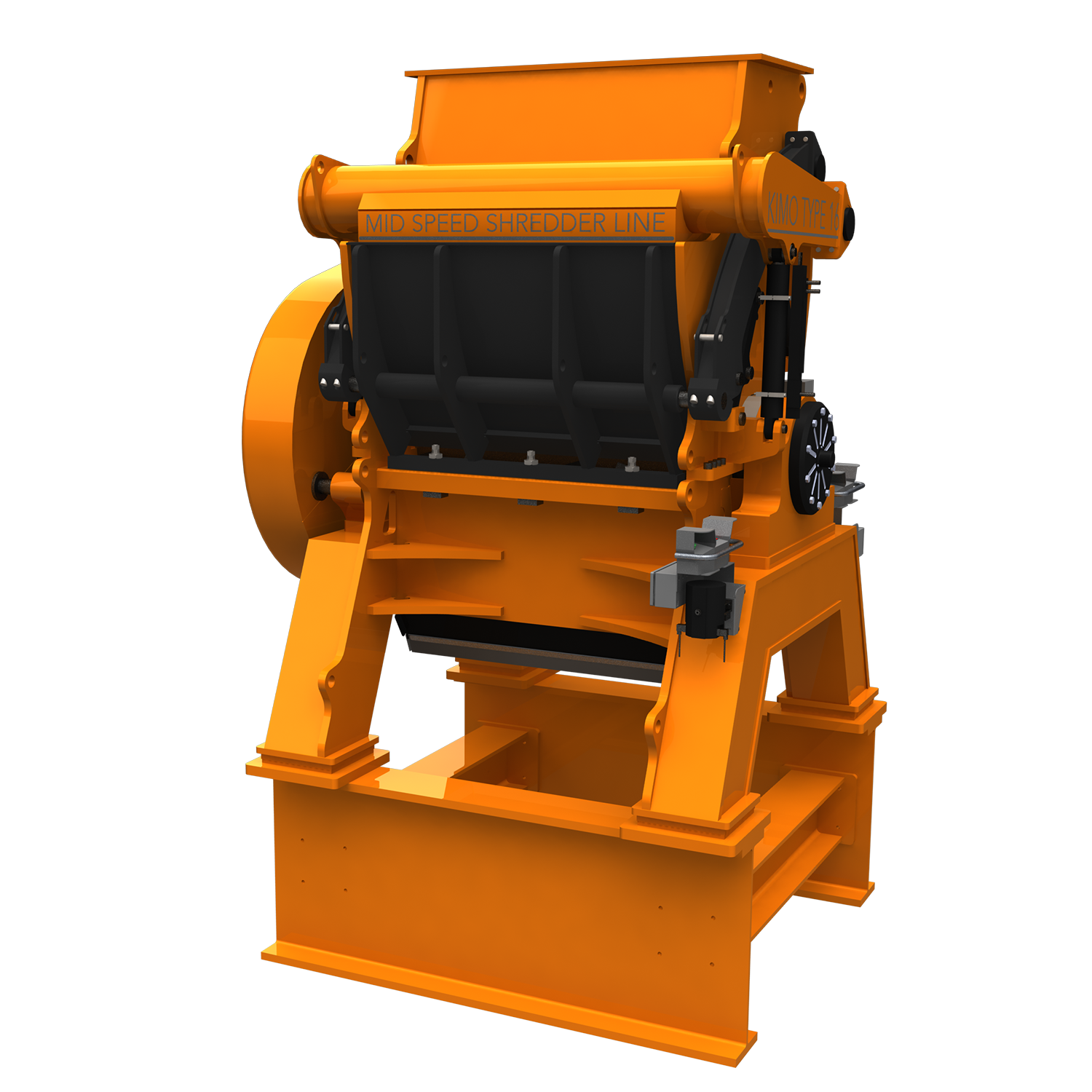

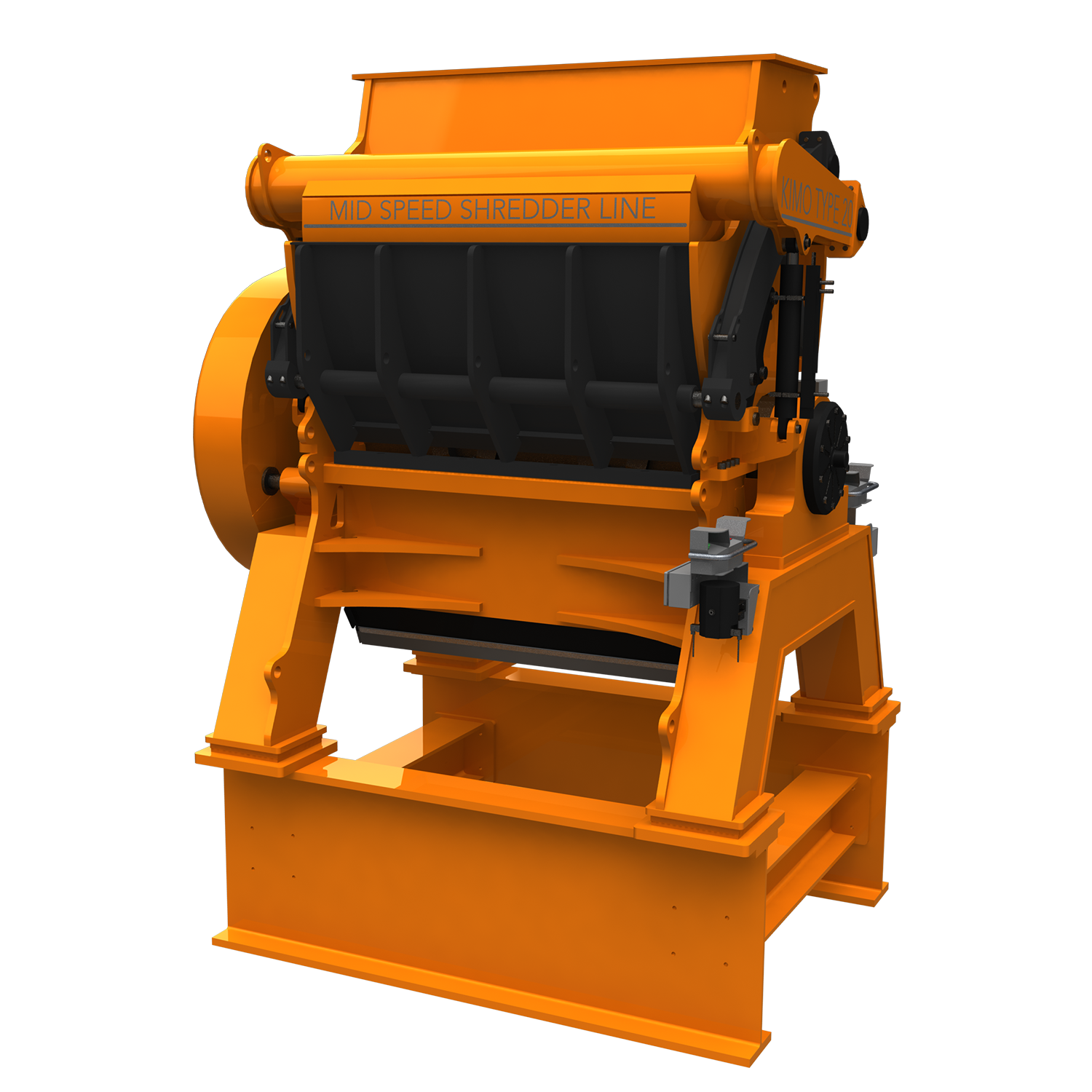

The KIMO Type 16 shreds everything – from plastic films and lightweight packaging to carpets and pre-shredded tires as well as aluminium or copper scrap. When fine shredding, the rugged KIMO can easily handle even larger solid contaminants as if they are nothing.

SPECIALS

The KIMO Type 16 primarily shreds pre-sorted, high and medium caloric residual materials to generate a product with even particle size for use as refuse derived fuel. It excels in particular where other cutting mills fail – even easily handling cable scrap, car radiators or electronic scrap with occasional electric motors of up to 1.5 kg.

The 1,600 mm long rotor of the type 16 is driven using a 250 kW three-phase motor. In conjunction with the large drive pulley, the rotor’s formidable diameter of 785 mm leads to a very high momentum of inertia (high flywheel mass). That rotating mass smoothens out any load peaks occurring in the process, allowing for an even and high workload of the relatively low powered drive, and thus low electric power consumption.

The KIMO Type 16 is not picky: When it comes to fine shredding different refuse derived fuels, it was designed with reliability and toughness in mind to ensure that even large contaminants do not slow it down. The generously dimensioned design and the support leg segments which are additionally weighted down with polymer concrete decrease vibrations. Thus, the KIMO Type 16 stays in place even in case of no additional anchoring.

APPLICATIONS

- Refuse derived fuel processing

BENEFITS

- Long service life as a result of its heavy duty, rugged design

- Low energy consumption due to relatively small motor

- High tool holder leading to larger shredding chamber volume and improved intake behaviour, and thus resulting in higher throughput

- Large drive pulley and rotor ensure high momentum of inertia and high power reserve for load peaks

- Low vibration due to heavy design end additional weight

- Easy to maintain due to large access panels and easy-to-change tools

- Adaptable friction clutch protects the machine against any damage due to foreign solid objects