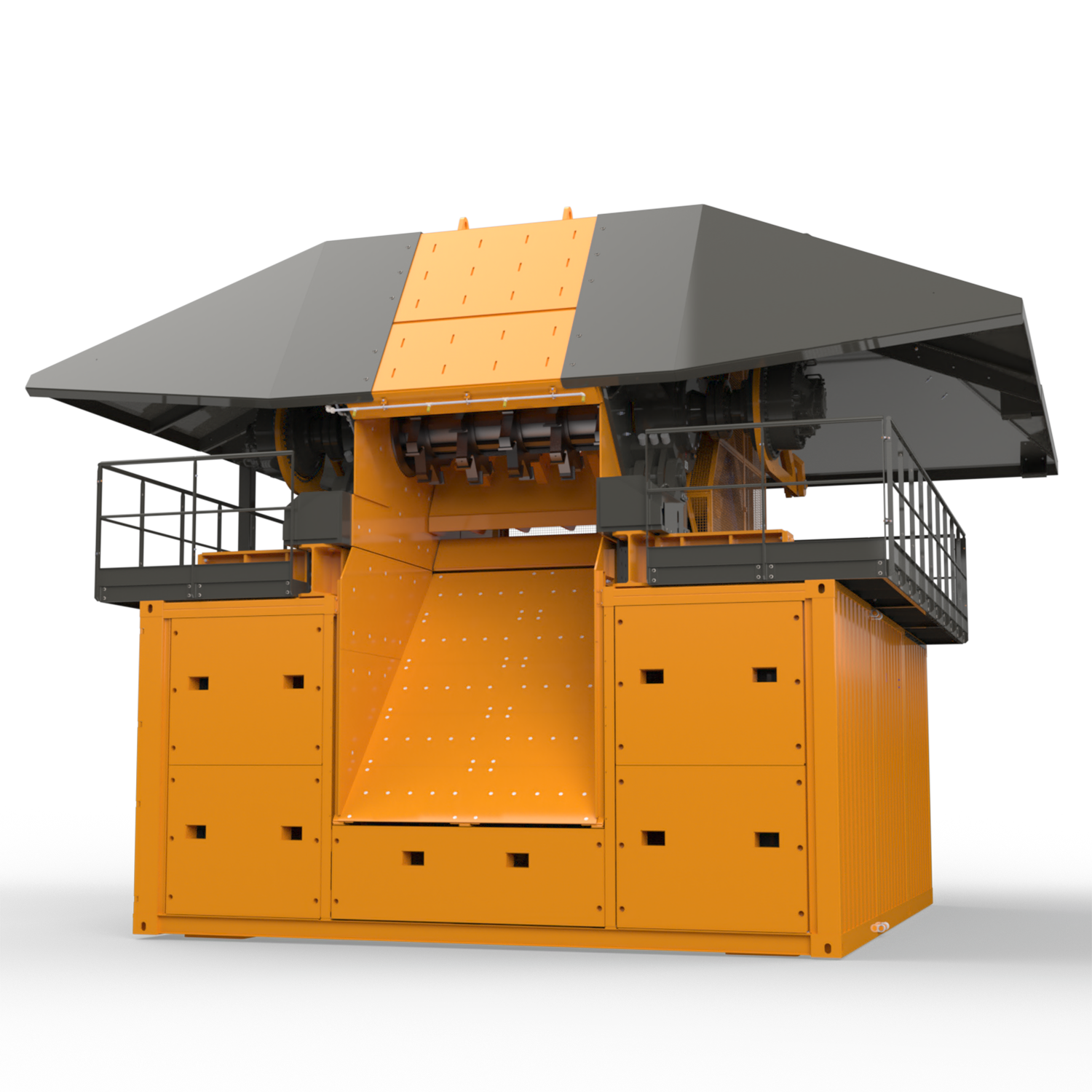

EZR ELECTRIC

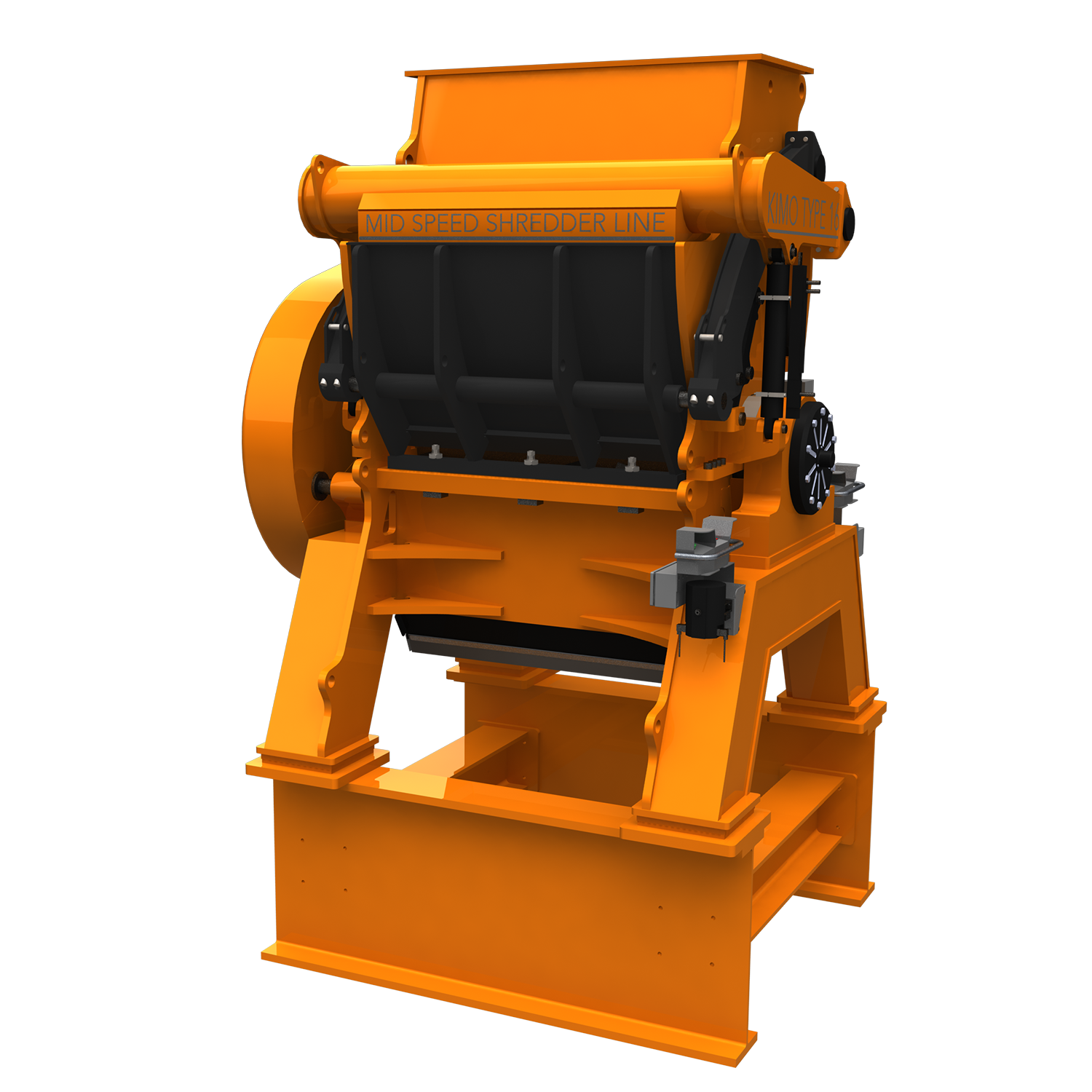

Shredding operations can be risky. Explosions and ungrindable material can damage the mill and cause critical machine downtime.

With MTB’s new pre-shredder range, ungrindable material is pre-processed to offset risks for the shredder. Oversized ungrindables are stopped and disposed of without risk of damage to the EZR. Slow shaft speeds in an open environment significantly reduce the risk of explosions and their consequences.

Our electric range (eDrive) is a true innovation, without equivalent on the market. A custom-made drive assembly with performance worthy of a hydraulic drive: 99T of force at the business end of the pre-shredder even at near-static rotation speeds. A new area has been created to process aluminium, low-density bundles and light scrap metal.