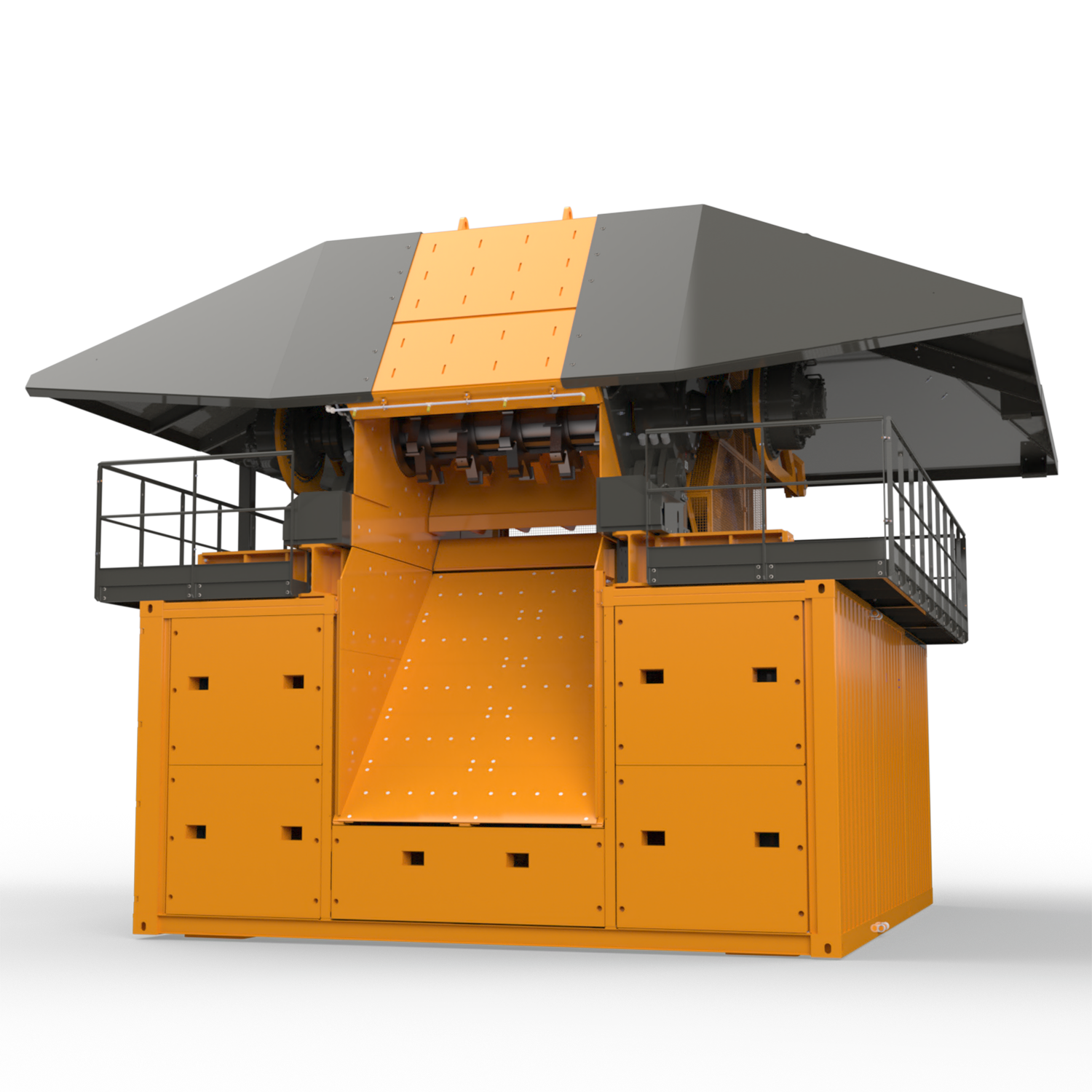

The low-speed CERON TYPE 206 shredder demonstrates its effectiveness especially when it comes to difficult shredding tasks and offers the opportunity to handle a large number of recycling tasks – while ensuring the highest level of tolerance to obstructions.

SPECIALS

The roller of the CERON TYPE 206, which is 2 m long and 0.6 m thick, uses its powerful teeth to tear the incoming material through the shredding comb. In the event that there are obstructions, the shredding comb opens automatically to prevent the occurrence of any damage. The features that make the stationary pre-shredder of the CERON series outstanding include a high throughput and the chunky composition of the pre-shredded materials.

Moreover, all of the machine’s wear and tear parts can easily be replaced in just a few simple steps. The level connection options in the infeed and discharge areas ensure that the machine is able to easily adapt to installation-specific conditions and that literally makes the CERON TYPE 206 always the right partner.

The machine is directly driven using AC motors. The speed can be individually regulated to ensure that the machine is always optimally adapted to the respective process requirements. Starting a loaded machine is not a problem either thanks to the new frequency inverter technology. Large safety doors and flaps facilitate the efficient and safe maintenance from outside of the machine.

The pre-shredders of the CERON series process waste wood, roots, green waste, bio-waste, household waste, bulky waste, commercial waste, construction waste and much more. This makes the machine well suited for a wide variety of tasks in the areas of mechanical/biological treatment, bio-mass processing or recovery of refuse-derived fuels.

APPLICATIONS

- Wast wood processing

- Composting

- Commercial waste recycling

- Refuse derived fuel processing

- Construction waste

BENEFITS

- Universally usable for shredding a wide variety of materials

- Versatile thanks to the different equipment options, wide range of tooth shapes, drive systems, stands or lower conveyor belts

- Less energy consumption thanks to efficient, frequency-controlled direct drive

- Very rugged design for an extra long service life

- Easy to service and maintain as a result of comb hatch that can be opened hydraulically, offering direct access to the shredding tools

- Shredding drum can be moved in jog mode to allow for a much easier tool change

- Very low noise emissions during operation

- Integrated misting equipment to reduce dust emissions