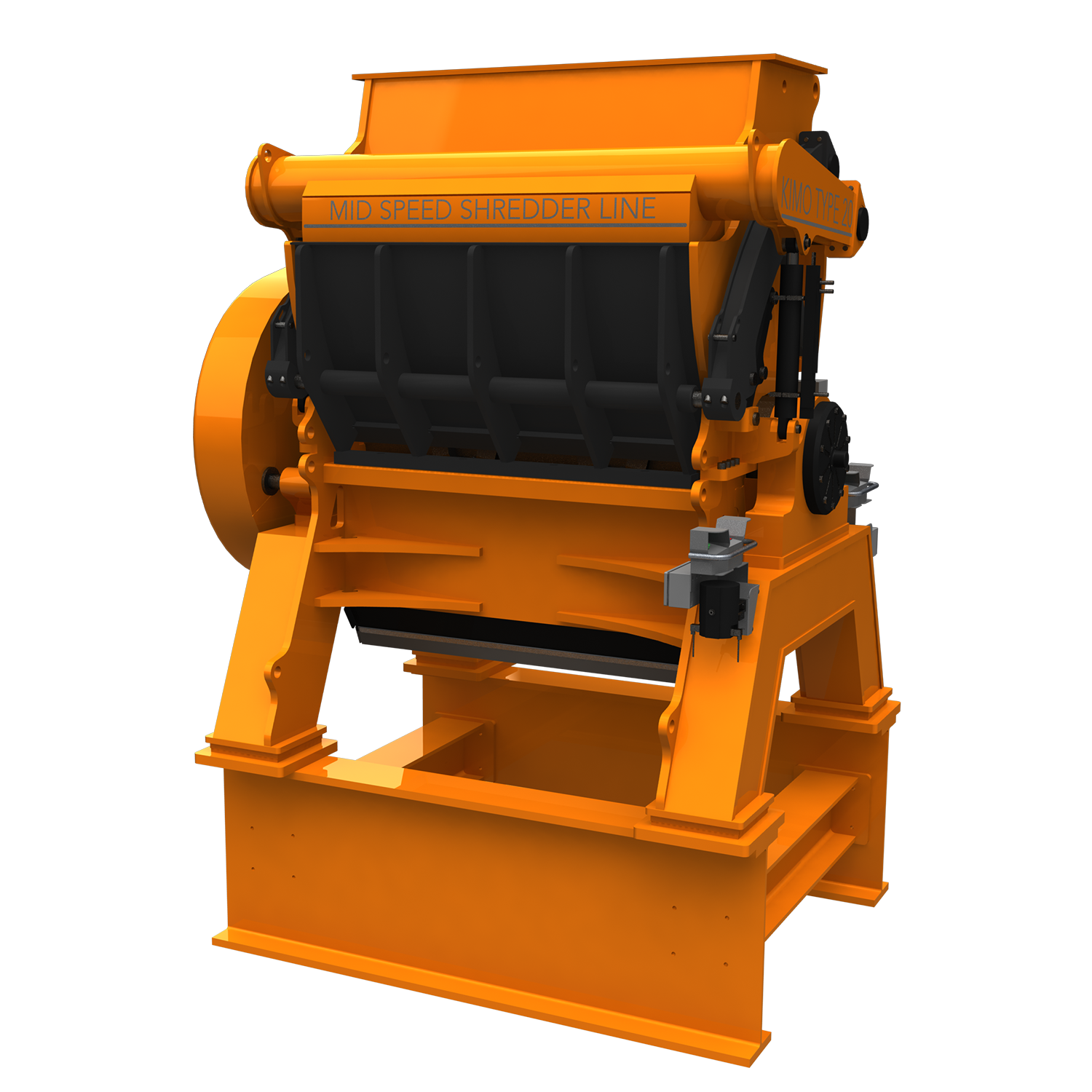

Its mighty 611 HP electric motor gives the stationary AK 640 VE fine shredder its great power and delivers impressive throughput. In addition, it impresses with its comprehensive range of accessories that further increases the machine’s output.

SPECIALS

With its 1.75 m wide flail drum, the AK 640 VE is ideally suited for use in composting and processing facilities, where it is necessary to process bio-waste, green waste, biomass and waste wood at high throughput rates. The overlapping flail rows ensure even better results in terms of shredding, since the flails are able to move freely and retract upon contact with oversized chunks, which contributed significantly to reduced tool wear.

When it comes to the scraper floor of the AK 640 VE, efficiency is top priority. It is equipped with 32 bars that ensure the swift transport of the shredded material. As with the main drive and the infeed roller, the scraper floor also has a load-sensing motor control unit, which optimizes the machine’s throughput and operational efficiency.

In addition to the standard equipment configuration, the AK 640 VE offers an extensive range of accessories: From lower belt and feed hopper attachment through to remote control and Profibus integration, there are a wide variety of options available for further increasing the machine’s performance and its flexibility when shredding bio-waste and green waste for composting, different wood grades for waste wood processing and biomass processing facilities as well as a variety of other shredding tasks for recycling.

APPLICATIONS

- Waste wood processing

- Composting

BENEFITS

- Main drive, scraper floor and infeed roller are controlled using the frequency inverter and are finely tuned to one another, thus ensuring an optimal utilization of the machine and a continuous material feed thanks to the electric direct load-sensing control of drive units

- Overlapping flail rows for improved shredding results

- Freely oscillating flails that retract in case of obstructions

- QuickChange system for rear basket

- Optimized safety system with sensorless standstill monitoring

- Easy to transport: The machine is delivered fully assembled with undercarriage and discharge conveyor

- Quick setup and startup thanks to BUS control, which results in a significant reduction in necessary cabling