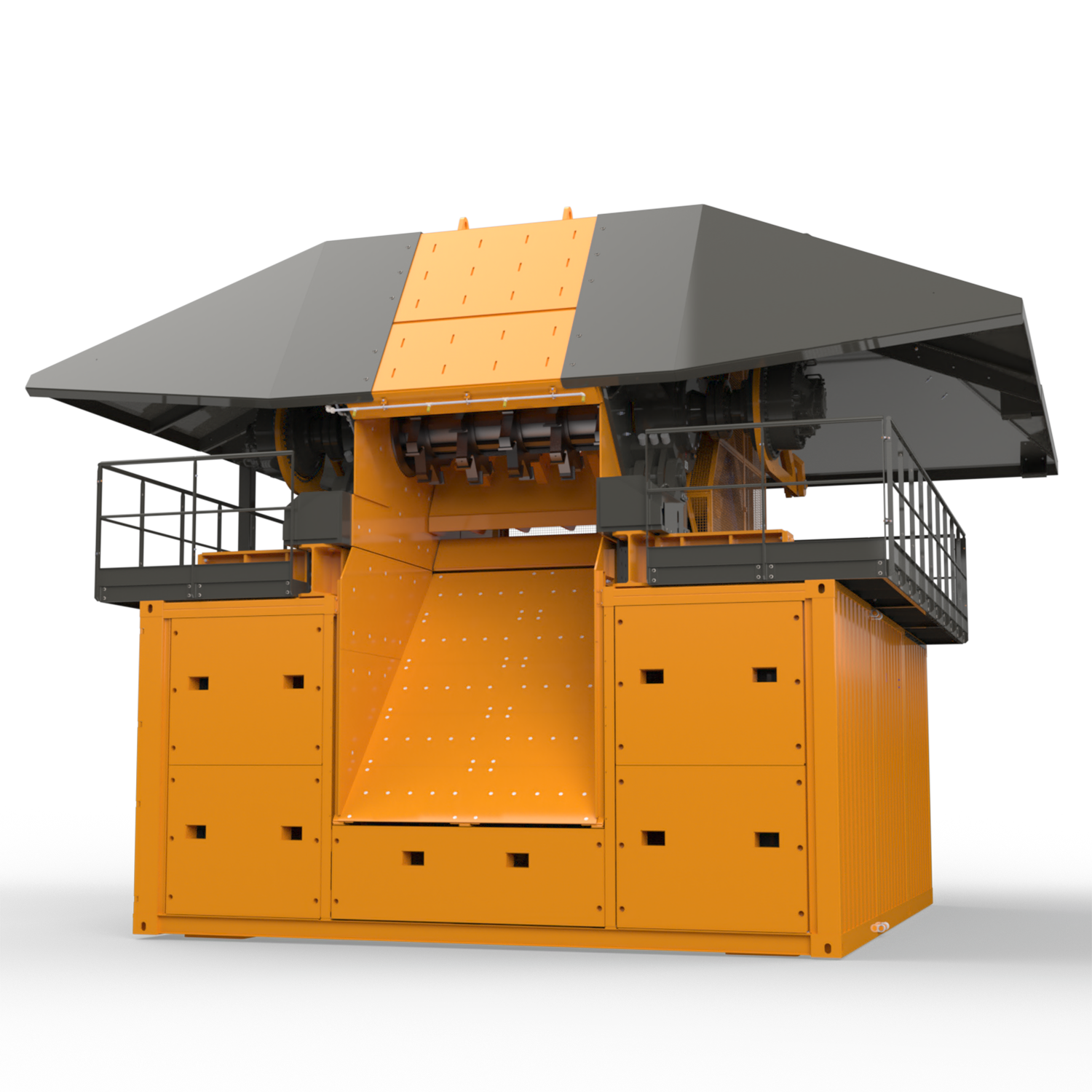

The AK 640 SA is the flagship of the AK series and delivers maximum throughput thanks to its huge feed hopper and state-of-the-art engine technology. At the same time, it is just as easy to transport as the smaller models.

SPECIALS

The AK 640 SA is distinguished by an optimal combination of performance, efficiency and flexibility. This is ensured, among other things, by the separate drive unit for the scraper floor and floating infeed roller as well as the material infeed system which is controlled in line with machine load and which ensures the continuous shredding of material and optimum system utilization.

The feed hopper with a width of almost 6 m makes it easy to feed the AK 640 SA, even with very large, oversized material. The discharge belt, featuring a length of 7.50 m and a width of 1.50 m, impresses not only due to its discharge height of more than 5 m but also due to the fact that it can be lowered almost all the way down to the ground, ensuring very easy and quick access to the flail drum, shredding tools and rear basket.

The easy replaceability of parts and high diagnostic capability of the machine allow for great ease of servicing and maintenance.

In spite of the dimensions of the AK 640 SA when operating, it can be easily relocated by boasting transport dimensions of 12 m (length) and 2.5 m (width). The new MTU 6R 1500 diesel engine with 20 kW of more power complies with the EU Stage V emissions standards. Other features further distinguishing this high-speed shredder include its exhaust system with its completely new stainless steel piping and the highly effective shielding of its exhaust aftertreatment system with integrated insulation optimizing the machine’s fire safety.

APPLICATIONS

- Waste wood processing

- Composting

BENEFITS

- Continuous shredding thanks to load-sensing material infeed, impervious to obstructions due to freely oscillating flails

- Latest engine and emissions control technology, compliance with the EU Stage V emissions standards

- Exhaust system made entirely of stainless steel

- 6 m feed hopper

- Standard lowerable rear conveyor (7.5 m long with a discharge height of more than 5 m) ensures very short set-up times and maximum accessibility and ease of maintenance for the flail drum, tools and rear basket

- Separate drive unit for scraper floor and floating infeed roller for optimum intake of materials and high output

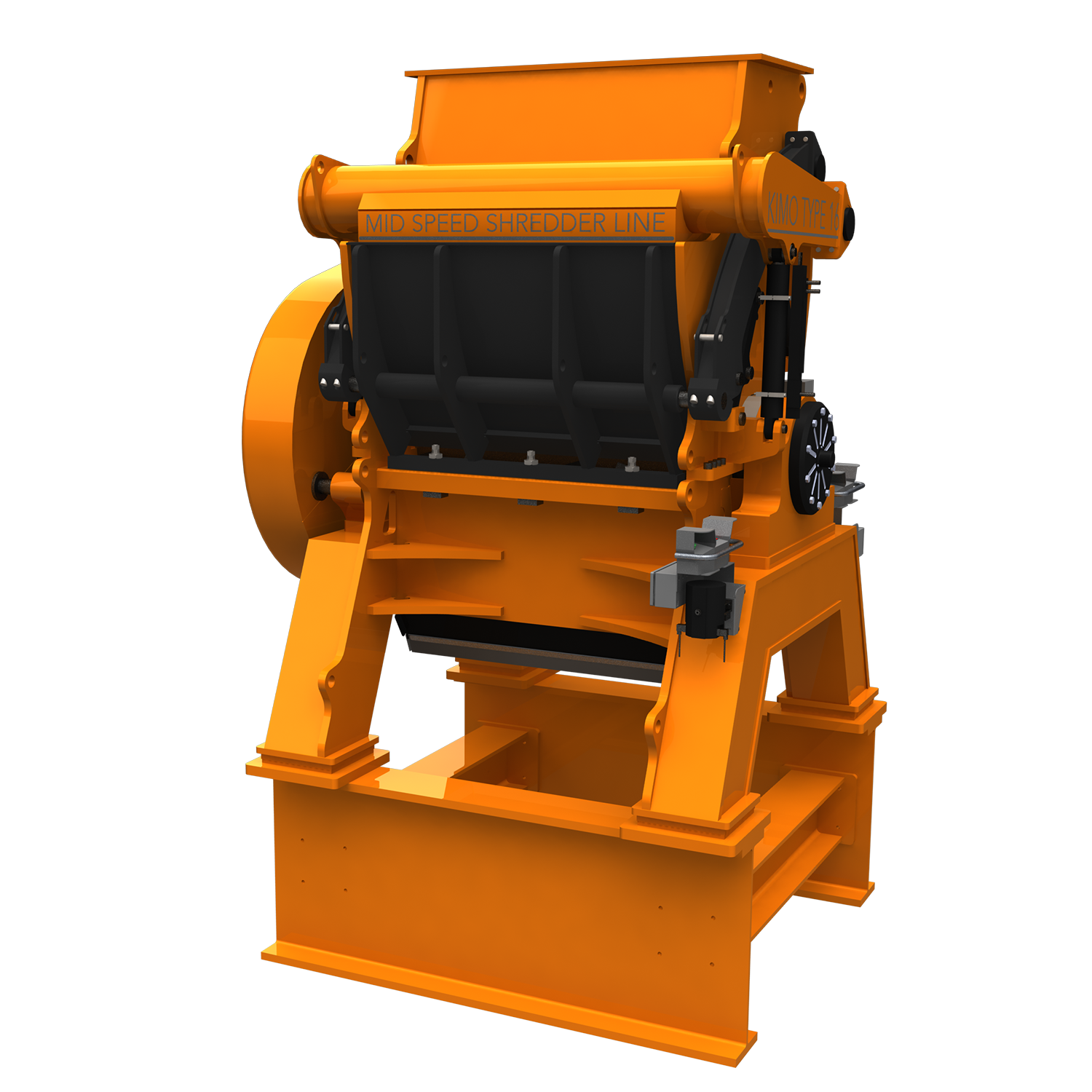

- Freely oscillating flails of the flail drum, with a flywheel mass of approx. 2.5 m. tons, have flail tips that can be replaced individually and adapted for specific materials (e.g. hard metal or armored tips)

- Special basket* with 3D technology for processing waste wood, for improving the structural composition of the end product (*optional)