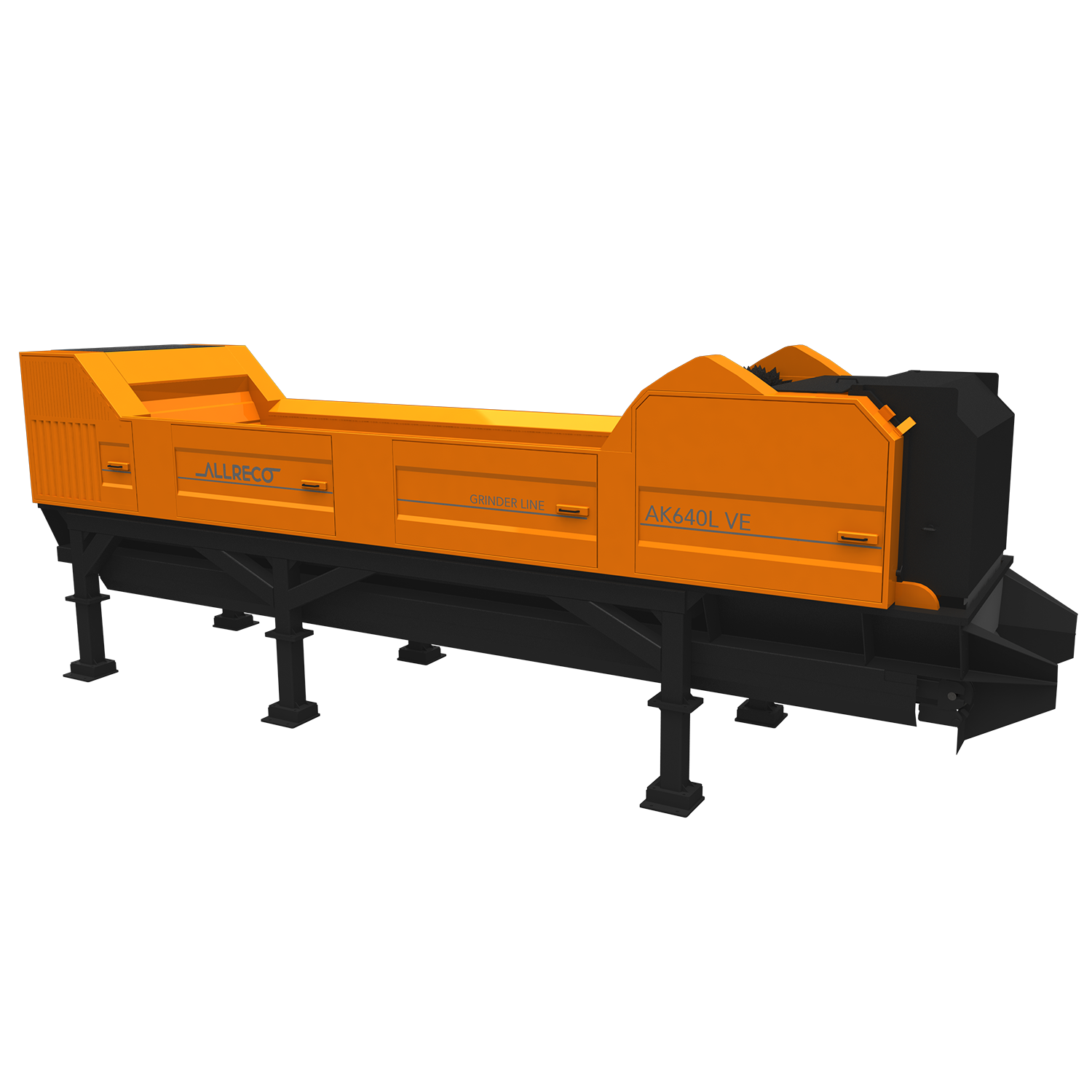

At almost 11 meters in length, the AK 640 L VE is the longest shredder in the series. In conjunction with its particularly wide feed area for large amounts of material, this makes the machine the ideal solution for operators that have to ensure continuously high output.

SPECIALS

When viewed from the side, the feed area of the AK 640 VE has been very spaciously dimensioned at approx. 5 m – and is thus optimally designed for accommodating large amounts of material. The AK 640 L VE is based on the same tried and tested shredding technology that is used in the smaller version, the AK 640 VE: The flails are attached in such a way that they can freely oscillate and avoid large obstructions in all directions.

The shredder delivers particularly good results due to the overlapping arrangement of the flail rows on the drum, thus improving its ability to grab the incoming material. The material is then quickly transported further into the machine via the scraper floor with its 32 bars, while the engine control relies on the load-sensing principle in order to ensure that the machine is optimally utilized at all times.

Even the AK 640 L VE can be flexibly upgraded with a wide variety of supplementary equipment, e.g. with a lower belt, feed hopper attachment and much more. That helps the largest member of the stationary AK series to set new benchmarks when it comes to shredding bio-waste and green waste for composting, different wood grades for waste wood processing and biomass processing facilities as well as a variety of other shredding tasks for recycling.

APPLICATIONS

- Waste wood processing

- Composting

- Refuse derived fuel processing

BENEFITS

- Main drive, scraper floor and infeed roller are controlled using the frequency inverter and are finely tuned to one another, thus ensuring an optimal utilization of the machine and a continuous material feed thanks to the electric direct load-sensing control of drive units

- Overlapping flail rows for improved shredding results

- Freely oscillating flails that retract in case of obstructions

- QuickChange system for rear basket

- Optimized safety system with sensorless standstill monitoring

- Easy to transport: The machine is delivered fully assembled with undercarriage and discharge conveyor

- Quick setup and startup thanks to BUS control, which results in a significant reduction in necessary cabling