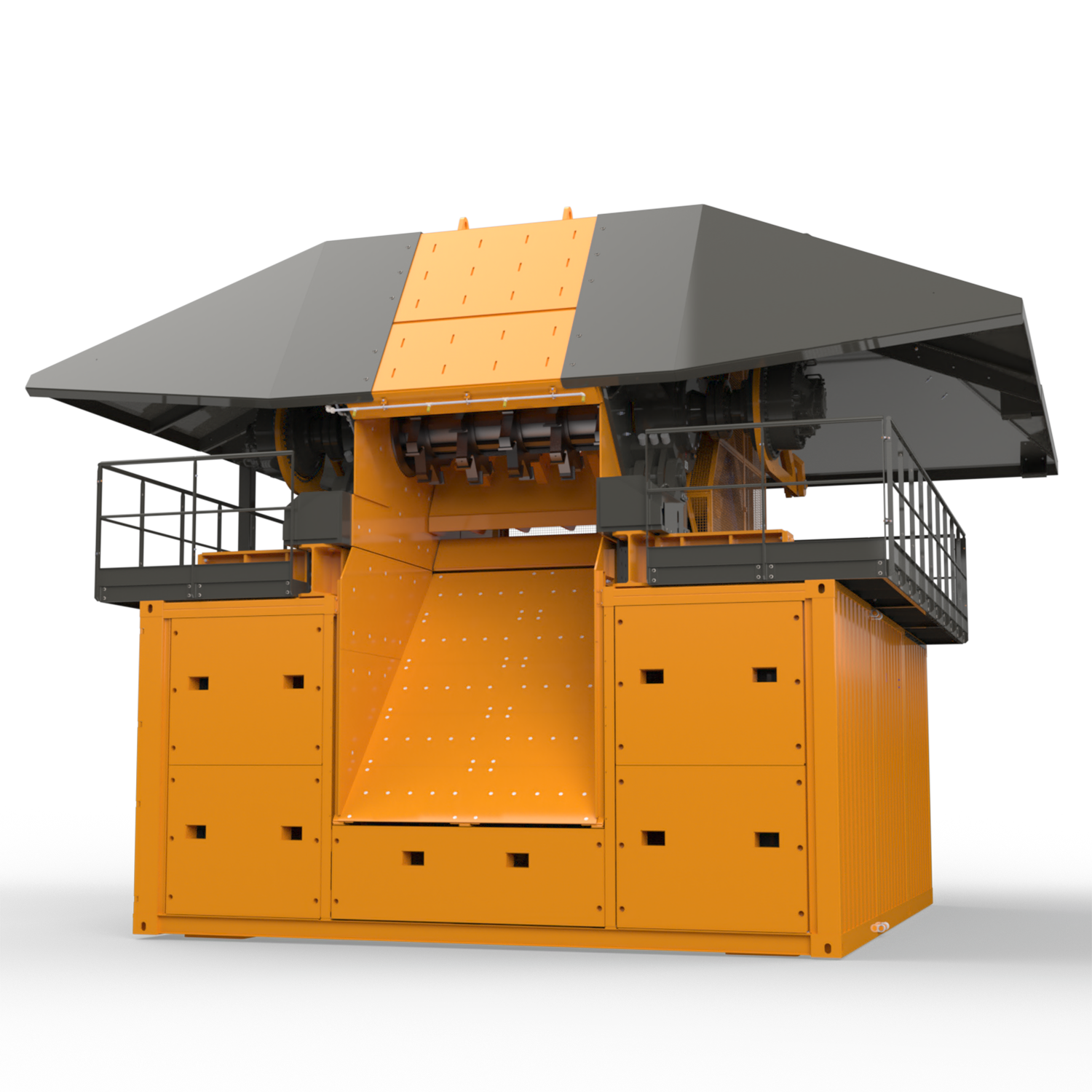

With a new, even more powerful main drive, the robust chain drive and the 7.5 m long rear belt with a discharge height of over 5 m, the AK 640 K is designed for the highest demands.

SPECIALS

The fine shredder AK 640 K is equipped with completely new stainless steel piping of the exhaust system. The exhaust aftertreatment system is optimally thermally shielded by means of integral insulation. The optimized diesel engine from MTU offers a plus in output (20 kW and 200 Nm). It has a rated output of 480 kW and fully complies with the latest Stage V emissions standard for non-road vehicles.

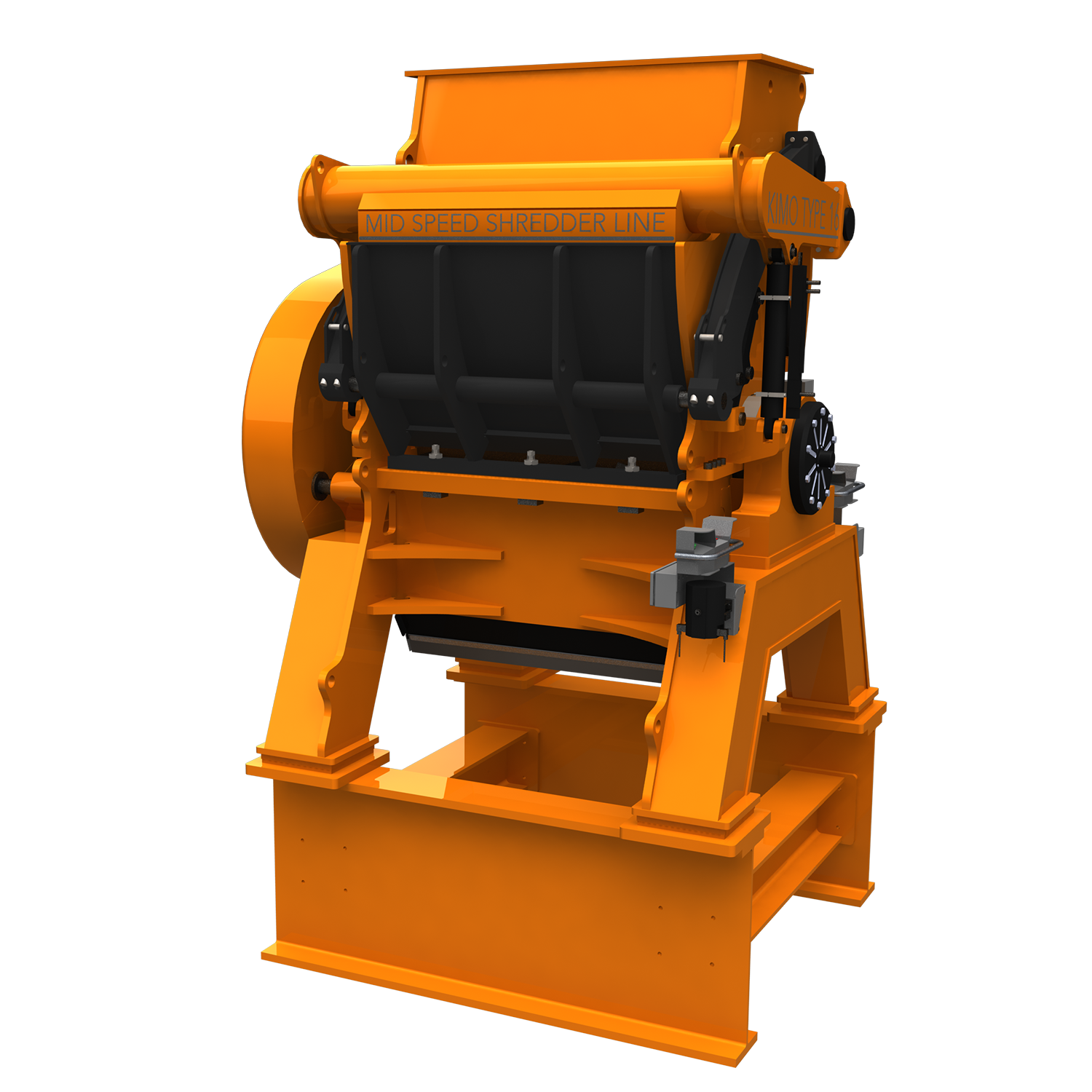

The successor model of the AK 635 K is characterized by the highest shredding performance. The AK 640 K can also process very large input material and is moved by a chain drive. If required, this is available in an off-road chassis variant, which increases the off-road capability with even more ground clearance. The 3,500 mm wide filling hopper with a loading height of 2,220 m and the 7.5 m long and 1.5 m wide discharge belt with a discharge height of over 5 m make the AK 640 K the perfect solution for a wide range of requirements.

The Doppstadt AK 640 K can be used for a very wide range of materials, such as for shredding waste wood, wooden pallets, green waste, organic waste or logs and roots.

The separate drive of the scraper floor and the pendularly mounted intake roller ensures an optimized material supply. The AK 640 K is easy to maintain thanks to the standard lowerable rear hinge, the high diagnostic capability and the easy interchangeability of the components.

APPLICATIONS

- Waste wood processing

- Composting

BENEFITS

- One-man operation (radio remote control of all functions), moving the machine using a chain chassis, high mobility in the field (* optionally also with 200 mm higher offroad chassis)

- Continuous shredding through load-regulated material intake, insensitive to contaminants thanks to free-swinging flails, the latest engine and exhaust gas technology, compliance with Stage V emissions standard

- Exhaust system made entirely of stainless steel

- Standard lowerable 7.5 m long rear conveyor (discharge height over 5 m) enables the shortest set-up times and maximum accessibility and ease of maintenance to the flail drum, tools or pushpit

- Separate drive of scraper floor and pendularly mounted intake roller for optimal material supply and high throughput

- Free swinging flails of the flail drum, with a flywheel mass of approx. 2.5 t, have individually exchangeable flail tips that are adapted to the material (e.g. hard metal or armored tips)

- Special baskets * with 3D technology for the use of waste wood for more structure in the end product (* optional)