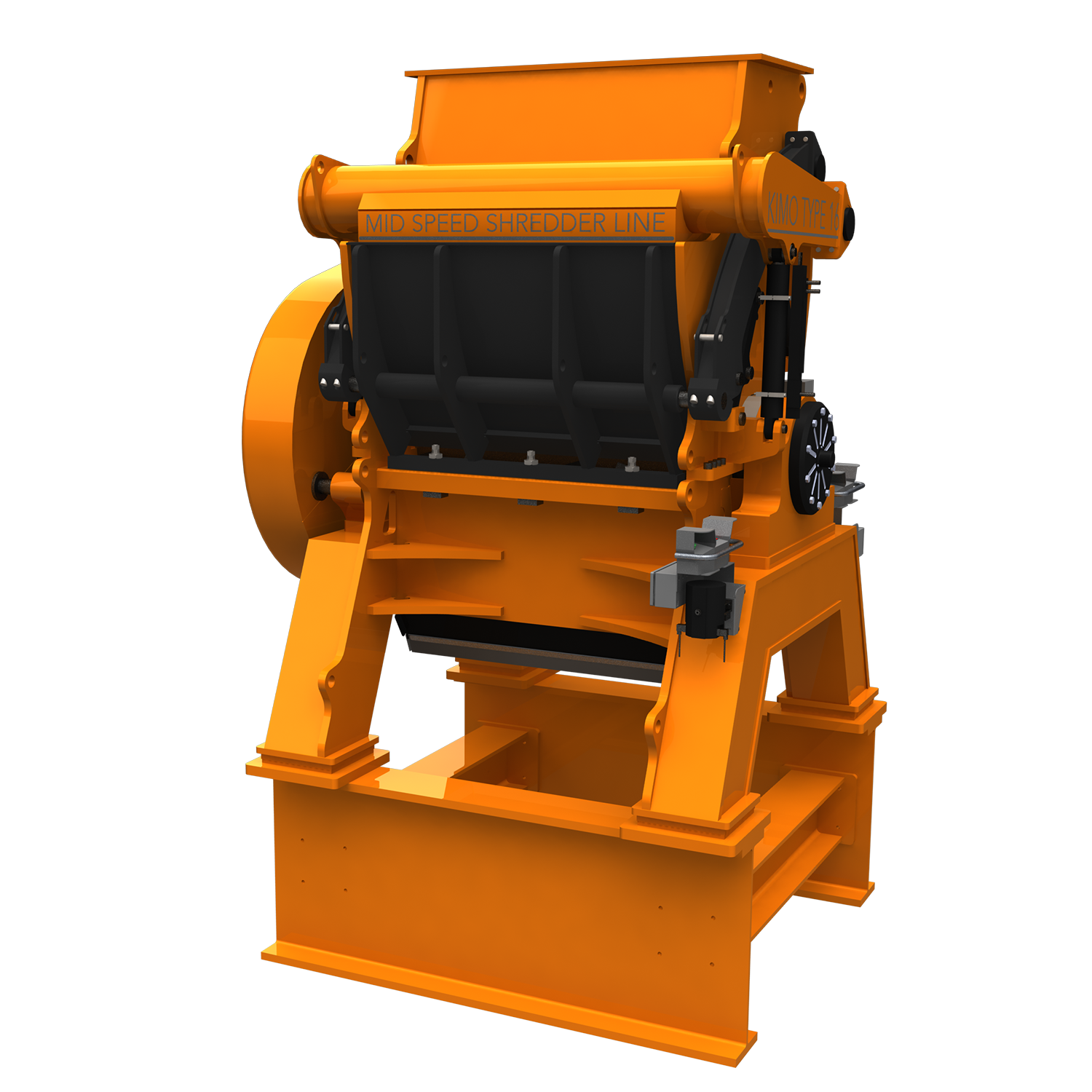

The smallest mobile shredder in the AK series, the AK 315 can be used for almost all shredding tasks, while its new 230 kW MTU engine meets the latest Stage V emission standards.

SPECIALS

The AK 315 can be used flexibly and universally. It’s equally suitable for shredding waste wood, wooden pallets, green waste, organic waste, tree stumps and root wood and for finely shredding solid recovered fuels. The heavy, two-row flail drum can be fitted with different flail tips to suit different materials and applications, while the optional fine shredding baskets in mesh sizes from 30 mm to 320 mm can be used to create different product formats.

The material feed is controlled by the load to ensure optimal power utilization and maintain consistently high throughput. When a certain pressure threshold is reached at the feed roller, it automatically reverses. The conveyor’s feed speed can be manually adjusted to suit the material requirements.

The optional lowerable rear discharge conveyor is hydraulically controlled for easy extension and retraction, and it can be fully lowered to enable maintenance work to be performed on the flail drum. Its discharge height of more than 3.5 m makes for easy transfer of shredded material to downstream machines or containers.

MTU’s powerful, state-of-the-art diesel engine features electronic torque optimization for high torque coupled with low fuel consumption. The large-sized, slow-running fan wheel ensures low-noise operation.

The new, decentralised electrics provide advanced diagnostic capabilities for easier troubleshooting.

APPLICATIONS

- Waste wood processing

- Composting

- Refuse derived fuel processing

BENEFITS

- latest engine and exhaust reduction technology, fully compliant with stage V exhaust regulations, exhaust system completely made of stainless steel, coated with high-quality integral insulation

- free-swinging flails of the flail drum (gyrating mass appr. 1,3 t (2,866 lb) are provided with easily individual replaceable flail tips that can be adjusted to the materials to be grinded (e.g. hard metal or armoured tips)

- resistant against contaminants thanks to free-swinging flails, continuous grinding by means of load-sensing material in-feed

- lowerable rear discharge conveyor for minimum set-up time and perfect maitenance friendliness and accessibility to flail drum, tools and rear basket

- discharge conveyor with length 6 m

- replaceable grinding basket*, the mesh size (30 – 320 mm / 1.2 – 12.6”) determines the material grain size, Special baskets* using 3D technology for the processing of waste wood, improving the structural quality of the final product. (*option)

- ideal for smaller facilities